|

PREVIOUS PAGE | 2770 INDEX | WOLLENSAK PRODUCT INDEX | MANUALS INDEX | NEXT PAGE |

|

2. 1.1 Head and Capstan

Accumulations of tape residue and other foreign material can cause wow and flutter, impaired erasure, reduced volume, and loss of high frequency response. These deposits -may be found on tape guide posts, capstan, capstan pressure roller, and heads. Perform the following cleaning procedure regularly, at least after every 10 to 12 hours of use.

3. Using your left forefinger or thumb, press back and hold the CARTRIDGE INTERLOCK lever located at the left rear of the cassette well.

4. Now, using your right hand, depress the START button to expose the heads.

5. Use a cotton swab moistened in methyl alcohol to clean the front of the heads.

CAUTION6. With the unit still running, place the moistened swab on the capstan and pressure roller.

7. Follow the above steps for all three modules.

2.1.2 General Cleaning

Clean the Model 2770AV and/or 2780AV Exteriors with a soft clean cloth. If it becomes very dirty, use a mild cleaner. Avoid excessive rubbing. Never use a thinner or strong chemical solution as this could damage the surface of the case and walnut sides.

2.1.3 Lubrication

The Wollensak 2770AV and 2780AV are factory lubricated. Additional lubrication is not necessary more often than every six (6) months, or before 500 hours of operation. Before applying additional lubrication, remove excess grease that has moved away from the point of lubrication. This grease picks up dirt and grit causing excessive wear or binding when not removed. Lubricate in the following manner:

1 . Re-apply Lubriplate or equivalent sparingly to areas where factory applied lubrication was removed in cleaning. In ideal conditions factory lubrication may last the life of the mechanism.

2. It should never be necessary to apply additional oil to Oilite bearings; but if oil is applied, never use a lightweight machine oil but rather use SAE 20 very sparingly.

2.2 PRELIMINARY TESTS

2.2.1 Introduction

Verify that the unit is not functioning correctly by attempting to operate the equipment as described in Section 1.

1 . Check to see that the AC plug is inserted properly into power outlet.

2. Insert pre-recorded cassettes of known quality into the Master and both Copiers3. Place the unit in DUPLICATION mode and inspect the tape path.

a. Is the tape wrap on the take-up spindle uniform and level?

b. Is the tape moving smoothly over the heads at a constant speed?

c. Is there abnormal slack in the tape?

4. Place the REWIND selector in MANUAL. The tape should immediately begin to rewind. Check for the following:

a. Is the tape wrap on the rewind spindle uniform and level?

b. Does the tape accelerate smoothly and rapidly onto the spindle?

8.

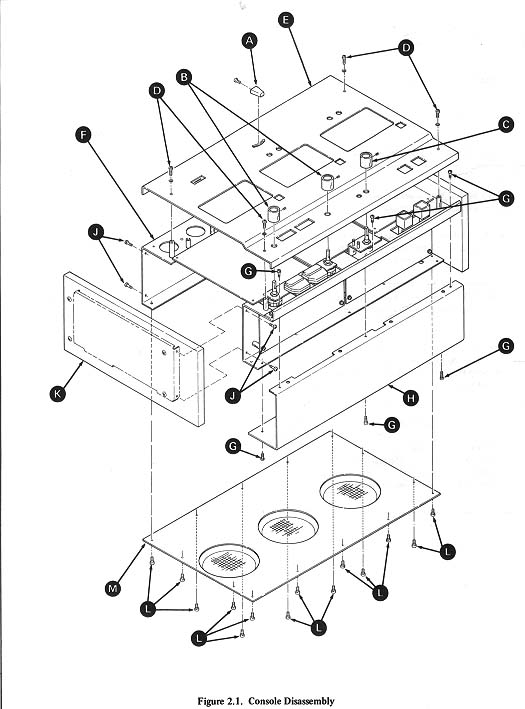

PLAY module only - when removing this module, two additional steps are necessary:

a. On Lot A units disconnect the three spade lugged wires from their

respective terminal strips. On issue one models disconnect the Molex connector.

b. Remove the two Phillips screws that secure the END-OFPROGRAM switch

mounting bracket. Lift the bracket up and relocate to the rear of the unit.

9. To remove the module, carefully and slowly pull the module straight out and away from the chassis. While removing the module, tuck in all wires that may cause an obstruction.

CAUTION

|

PREVIOUS PAGE | 2770 INDEX | WOLLENSAK PRODUCT INDEX | MANUALS INDEX | NEXT PAGE |

|