![[SJF Logo]](../images/sjflogo.gif)

| 1' - Genesis Audio & Video

| 2' - Genesis Audio & Video

...

| 999' - Genesis Audio & Video

| 1000' - Genesis Audio & Video

When an installer for Genesis Audio & Video was onsite to install a sound system, he would note the foot marker at the start of the project, note it at the end, and the difference would be how much cable was used on the job. This saved having to measure each cable used individually and was a much more reliable measure for job costing.

I was responsible for creating the software and controller hardware that allowed a machine operator to enter the phrase and length on a PC, and my system would take care of driving the whole process. The name "Impresor" is derived from a Spanish word for "Printer".

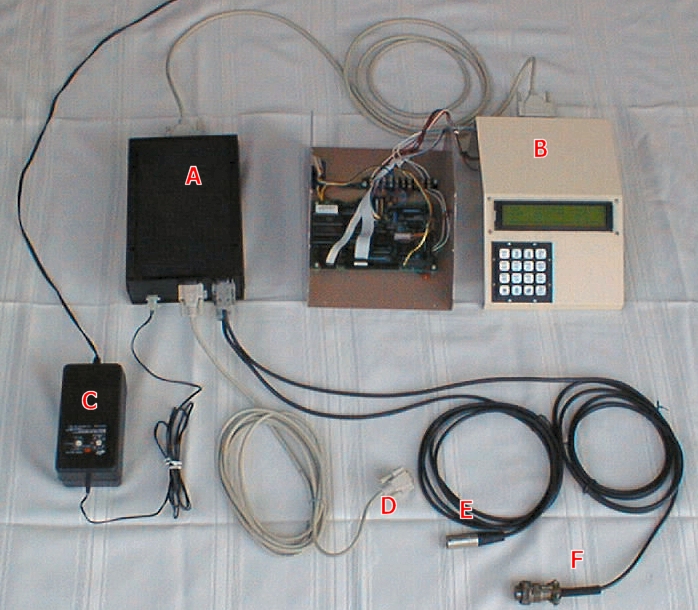

We used a Domino Amjet production-line inkjet printer that had a wire-carriage mechanism, inkjet spray head, and an encoder wheel that let us know how much and how fast the cable was flying past the printhead. The hardware system I created that linked the PC to the printer looked like this:

The labeled items are described as:

![[Rendesvous Box-small]](../images/Impresor-rendesvous-small.jpg) This was a mostly passive unit that merely routed the various signals where

they needed to go. This unit was mounted out of the way and had only a single

cable connecting it to the main control unit (item B, below), and this gave

us a lot more flexibility: we didn't wish the controller box itself to have

so many cables running to it that would make it harder to move around.

This was a mostly passive unit that merely routed the various signals where

they needed to go. This unit was mounted out of the way and had only a single

cable connecting it to the main control unit (item B, below), and this gave

us a lot more flexibility: we didn't wish the controller box itself to have

so many cables running to it that would make it harder to move around.

There is a small amount of active logic that helped condition a few of the

signal lines that went to the printhead controller, but it's mainly just

wires on the inside.

![[Control Unit-small]](../images/Impresor-control-small.jpg) This housed the processor, LC display and the keypad. The heart

is a Remote Processing RPC-320

embedded controller with an 8031 processor, 512KB of RAM, a high-resolution

encoder input, and plenty of other I/O lines. With the built-in BASIC

interpreter, it was easy to program this device over a serial line.

This housed the processor, LC display and the keypad. The heart

is a Remote Processing RPC-320

embedded controller with an 8031 processor, 512KB of RAM, a high-resolution

encoder input, and plenty of other I/O lines. With the built-in BASIC

interpreter, it was easy to program this device over a serial line.

It drove a 40 character by 4 line LC display that had software-controlled backlight for low-light shop conditions.

![[LC Display]](../images/Impresor-LCD-small.jpg)

The keypad let the machine operator

make immediate adjustments to the job without having to go through the PC.

I used the keypad all the time to adjust internal parameters while working

out the encoder timings (they proved to be very sensitive to cable speed).

Once the motor controller starts moving the wire, the wire encoder counts out pulses indicating movement. Since the encoder wheel was a known size, we could compute how many pulses yielded one foot of wire. These encoder pulses went into the Impresor control box, and once it counted the proper number of pulses, it sent a "Print Go" signal to the Domino Codebox. This triggered the inkjet printing the next message, and once we finished the job we'd simply not send the print messages any longer.

The control software was several hundred lines of BASIC, and though the details cannot be of any practical interest, they do convey a style of development. The source code is in printmaster.txt. A representative Pascal module is codebox.txt.

The system has long been out of production and we don't have any screen shots of the Windows portion of the system.